|

Jeep Cherokee

Neutral

Safety Switch Repair Procedure

Because mis-alignment, corrosion, and dust or water entering

the Shift Position Sensing Unit (AKA Neutral Safety) switch can cause a

multitude of malfunctions of the AW4 automatic transmission, it is a good

idea to check it out before assuming you have a bad transmission or Transmission

Control Unit. These problems may be intermittent so can be very hard to pin down

at times. The switch is quite expensive to purchase a new one, but is

easily adjusted or taken apart and cleaned.

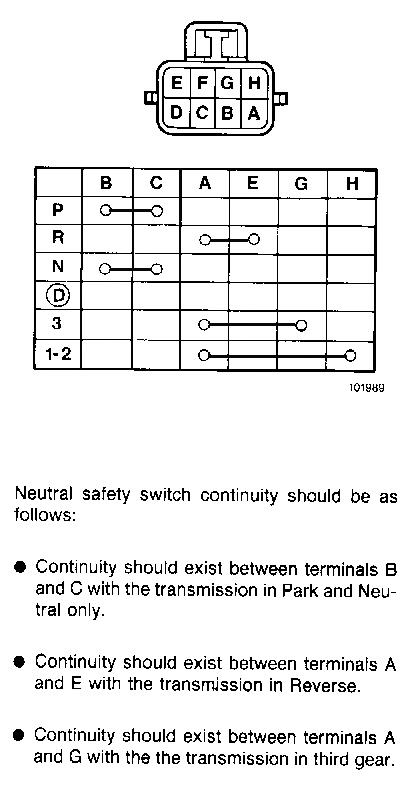

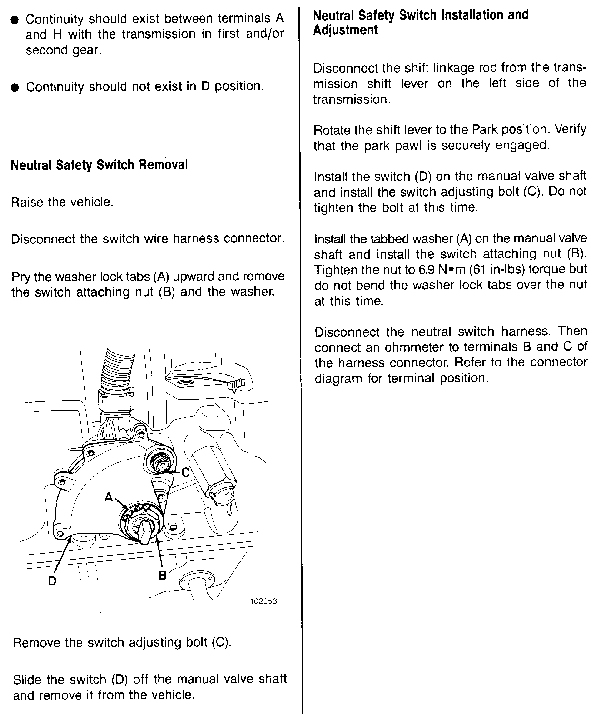

You can check out the switch before removing it from the

transmission by using a ohmmeter at the plug where it connects to the wiring

harness. The plug is located on the passenger side of the engine compartment

next to the firewall. You should read continuity according to the instructions below.

If you read any resistance and not total continuity in any of the pins on the

plug when moving the shift lever then remove the switch and clean it. Be

sure you are on level ground with the parking brake set, the wheels blocked, and

engine off prior to

testing or removal of the switch. The instructions from the Cherokee Repair

manual for removal, replacement and adjustment are found below.

Note: Part of the switch housing is a plastic

material. When removing the switch it may be hard to slide off of the

shaft because of a build up of dirt and corrosion. You may want to spray

it with a penetrating oil and let it set for a while before trying to remove

it. Be careful when prying it off of the shaft or the plastic housing may

crack.

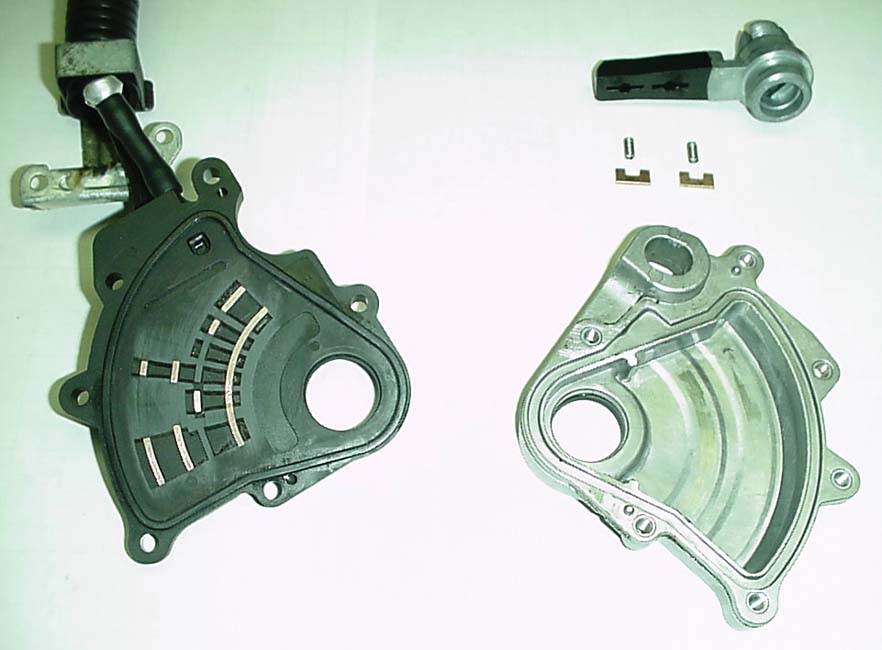

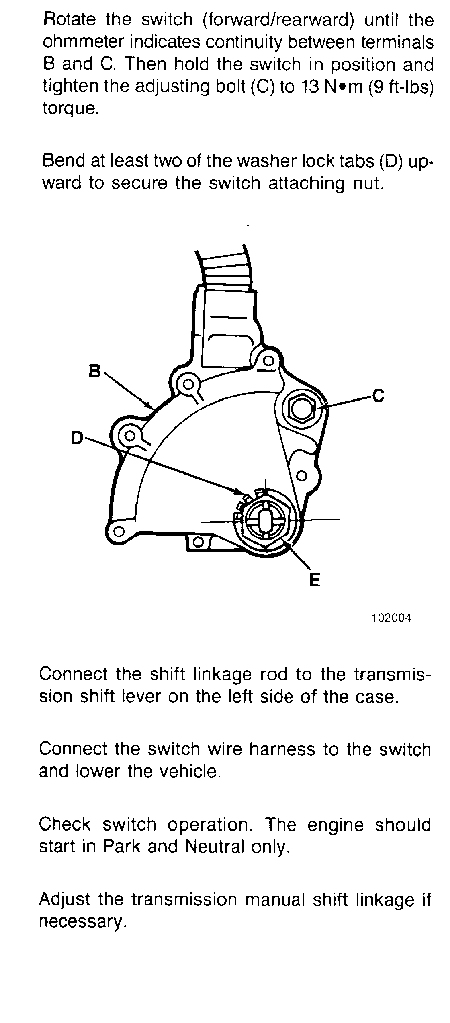

The pictures of the disassembled switch are courtesy of

Frank Barnes, who had installed the CompuShift Plus but still had shift

problems. I suggested to him that it might be the 1-2 position switch on

the transmission that was causing him problems so he said he would check

it. What he found is that the switch was, as he put it, "full of

crap" and was causing intermittent transmission and backup light

operation.

Because of the fact that the switch has eight separate contacts

and two sets of wipers you can have problems in only one area of the switch and

circuit while everything else functions fine. So you cannot just assume

that if it starts ok in park or neutral that all of the rest of the contacts are

fine.

The switch is held together by Phillips screws and is not sealed

so it can be taken apart quite easily. After removing the screws it is a

simple matter of removing the wiper arm and its two springs and contacts.

You can then use a contact cleaner to spray both halves of the switch assembly

taking care to make sure that all the contact surfaces on it and the wiper arm

are clean and bare. Replace the springs and contacts into the wiper arm and

reassemble it to the case with the contacts on the wiper arm facing the contacts

on the wired side of the assembly then apply a light lube or grease to the arm

where it goes through the hole in the other half of the assembly and also to the

back side of it (opposite the contacts) where it rides on the assembly case.

Take care not to get any on the contacts themselves. If you wish use a light

silicone or other sealant on the edges of the case before tightening the screws.

This will help to keep out any new contamination. Re-install and adjust

the switch according to the directions below.

Disassembled Neutral Safety/Back Up and 1-2 Switch

Transmission Position Sensing Unit Connector.

Home

|